Transparent conductive metal oxide

Varied range of applications

| |

Change of specification: S302 and S2002S1 are now 1mm thick (from 1.1mm) and S2004S1 is now 2.1mm thick (from 2.2mm).

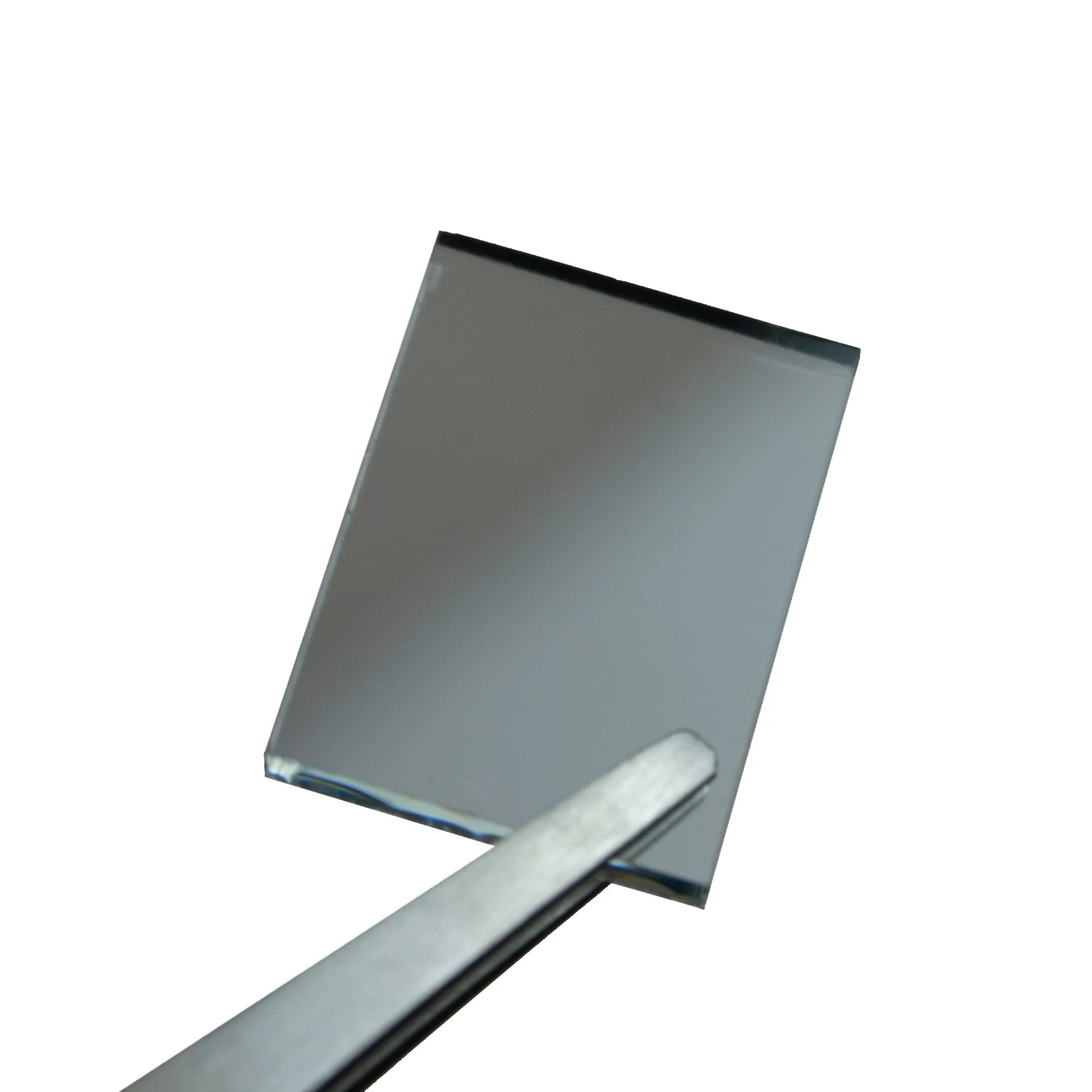

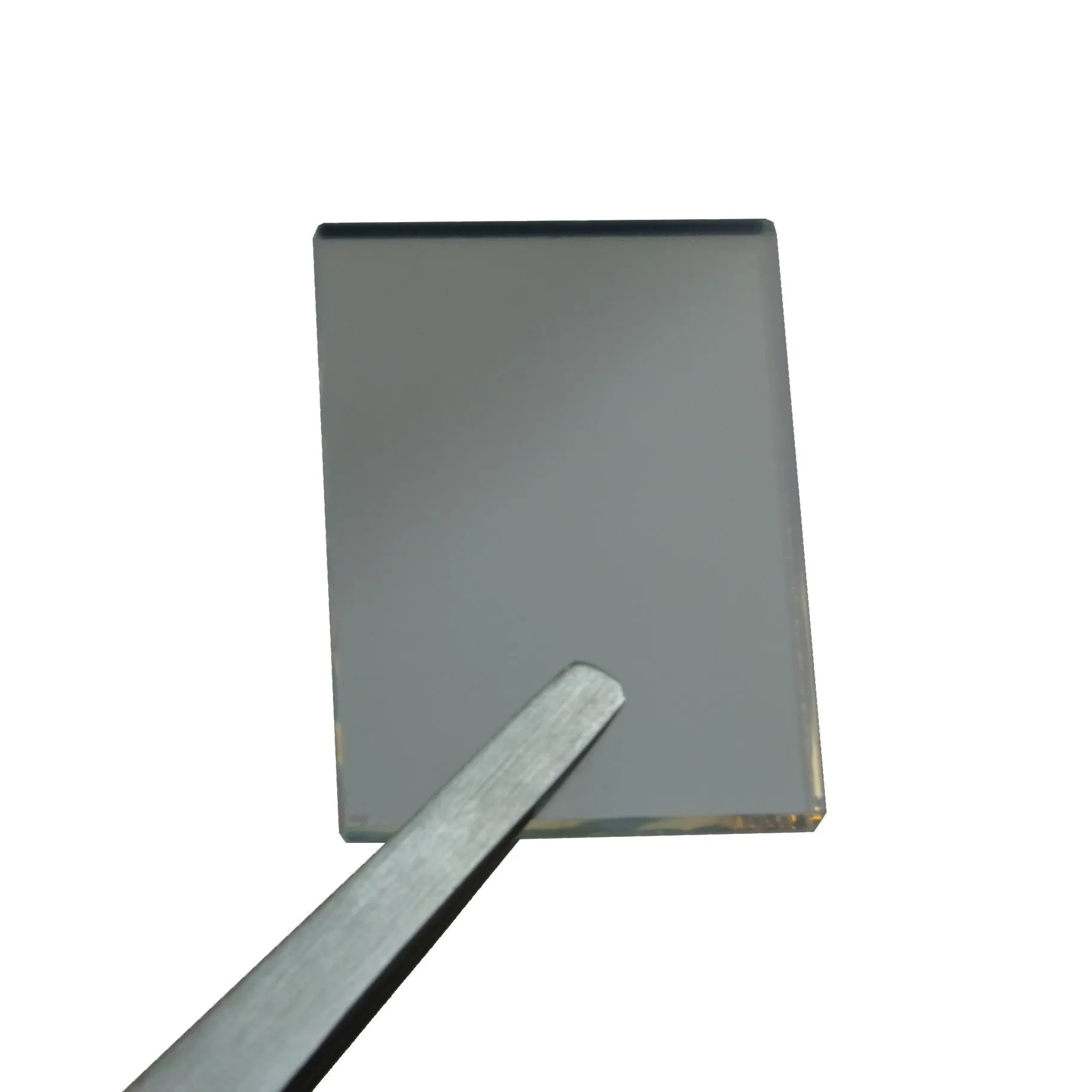

FTO (Fluorine-doped Tin Oxide) glass is a transparent conductive metal oxide that can be used in the fabrication of transparent electrodes for thin film photovoltaics, such as: , amorphous silicon, cadmium telluride, dye-sensitised solar cells, and . FTO glass also has a varied range of other applications, including touch screen displays, electromagnetic interference/radio frequency interference shielding, heated glass, anti-static coatings, and light-emitting diodes. There are several properties of FTO glass that make it suitable for the fabrication of a wide range of optoelectronic devices: these include low surface resistivity, high optical transmittance, scratch and abrasion resistant, thermally stable up to high temperatures, and inert to a wide range of chemicals.

Ossila supply three types of FTO-coated glass for sale: TEC 8 (2.2mm thick glass), TEC 10 (1mm/3.2mm thick glass), and TEC 15 (2.1/2.2mm thick glass). Each offer different conductivities and surface roughness to suit a variety of applications.

- TEC 8 FTO offers the highest conductivity for applications where low series resistances are crucial.

- TEC 10 FTO offers both high conductivity and high surface uniformity where both properties are crucial for the fabrication of high performance electronic devices.

- TEC 15 FTO offers the highest surface uniformity for applications where thin films are to be used.

Specifications and data files for Ossila’s range of FTO-coated glass can be seen below, along with processing guides for the etching and cleaning of the FTO coating.

Datasheet

| Substrate | TEC 8 | TEC 10 | TEC 15 | |||||

| Product Code | S301 | S2001S1 | S302 | S2002S1 | S303 | S2003S1 | S304 | S2004S1 |

| Size | 20mm x 15mm | 25mm x 25mm | 20mm x 15mm | 25mm x 25mm | 20mm x 15mm | 25mm x 25mm | 20mm x 15mm | 25mm x 25mm |

| Glass Thickness | 2.2 mm | 1 mm | 1 mm | 3.2 mm | 3.2 mm | 2.2 mm | 2.1 mm | |

| Glass Type | Soda Lime Glass | |||||||

| FTO Type | NSG Tec 8A | NSG Tec 10 | NSG Tec 15 | |||||

| FTO Thickness | 600 nm | 750 nm | 400 - 450 nm | |||||

| FTO Quoted Sheet Resistance | 6 - 9 Ω/square | 11 - 13 Ω/square | 12 - 14 Ω/square | |||||

| FTO Measured Sheet Resistance* | 6.70 ± 0.27 Ω/square | 9.39 ± 0.38 Ω/square | 12.46 ± 0.50 Ω/square | |||||

| FTO Roughness | 34.8 nm | 45 nm | 12.5 nm | |||||

| FTO Work Function | 4.4 eV - 4.7 eV | |||||||

| FTO Transmission | 76.4% | 83.4% | 83.5% | |||||

| Packaging | Adhesive-free surface protection tape and cardboard box | |||||||

*Sheet resistances measured using the .

Currently, Ossila does not offer custom substrate sizes. We may offer additional sizes in the future based on demand. If you would like to make a suggestion, then please leave a request on our .

Transmission Spectra

Below are the transmission spectra for the different types of FTO, the graphs can be viewed full-size by clicking on the thumbnails.

| TEC 8 | TEC 10 | TEC 15 |